Remove the pump. After verifying that no fuel was getting to the front he got under the tank and banged it with a hammer a couple times as I hit the ignition and Presto.

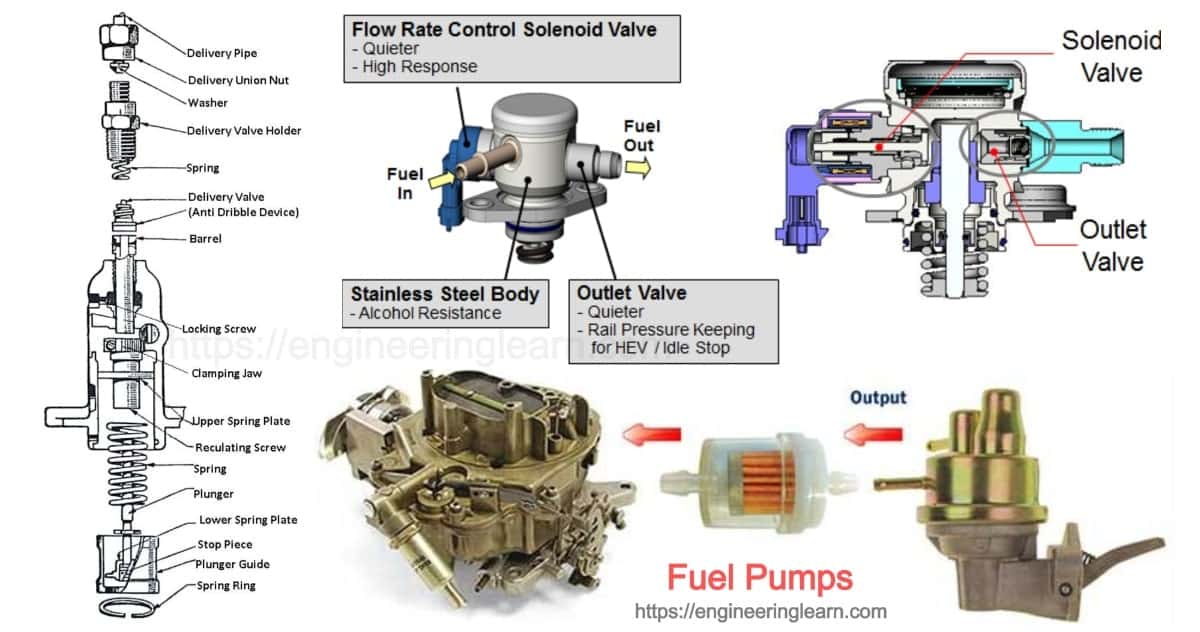

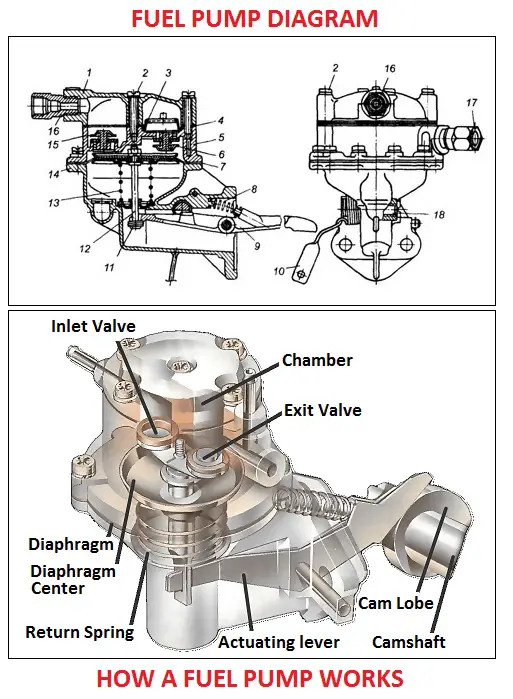

Types Of Fuel Pumps Mechanical Electric High Pressure Fuel Pump Engineering Learn

No need to take it all apart yet.

. Clean off any old gasket material from the mounting surface of the. There will be a nut or a bolt sticking out of the top of the mechanical fuel pump that holds the cover over the fuel filter. 12 volt positive with large enough wire to support fuel pump needs will land on 30.

He told me the pump was going bad and to get it replaced ASAP. Reinstall the spacer plate use a new gasket. Went down to the local marina and they happened to have the diaphramrebuild kit in stock however it did not come with the gasket that seals between the filter housing top and the check valve section of the fuel pump body.

Put a plug into the inlet fuel line to stop fuel leaking. The key is to not actually take it all apart just remvoe the scres and rotate it. Take the inlet nut off and see if it has a bronze filter in it and take it out if it does.

What I find often is that I look at a product we sell here at. Disconnect the outlet line to the carburetor. Add Article To List.

With the factory Carter Mechanical fuel pump. Carefully examine the old fuel hose. Racing mechanical fuel injection jetting is made up of nozzles to the engine and one or more bypass pathways back to the fuel supply.

For rubber lines this will typically involve removing a hose clamp. If youre lucky enough to have an original Carter X fuel pump on your car youre truly among the elite in the Mustang world. An alternative is to remove the spacer plate and push rod and put some heavy grease on the push rod.

I have a 37 Merc. This grease will for a while hold the pushrod to the cam in the retracted position. Surge Tank Wiring Diagram.

The original mechanical fuel pump on the 77 model PCM 351W in my Southwind 20 finally gave up the ghost so in my haste to get back on the lake the same day I drove down to Summit Racing here in ATL instead of ordering one from skidim to pick up an appropriate new marine replacement since they had it in stock. Because the X pump was used only on the Boss 302 and 429. 87a will run to 12 volt positive on fuel pump itself.

He then said something about some magnets in the pump wearing down and losing contact and what not. Remove the cap of the fuel filler and bring your ear close to its opening. Find it and then use the correct sized wrench to.

The positive displacement fuel pump with the jetting layout makes a linear fuel curve with engine RPM. Then pull the needle and seat out and spray some cleaner through it. If it is frayed or cracked replace it with new fuel line hose.

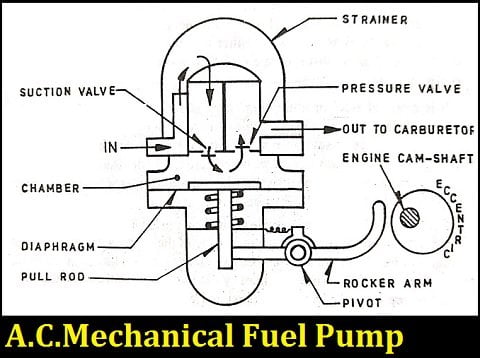

Once you have the pump apart and cleaned inside and out you will be able to inspect it for any obvious damage as well as see how to disengage the actuating links that operate the diaphragms. Use a wrench on the fuel pump fitting and another on the line nut. Before you take the flange screws out file a line across the edge of both flanges to indicate the position for re-assembly.

Other engines will require that you remove the line from the carburetor with a wrench. Some things require no explanation and well some things need a lot of explanation. This will remove the pump completely from its housing.

Disconnect the hose that connects the fuel pump to the carburetor. Installing a Mechanical Fuel Pump. Place a rag over the end of the open fuel line.

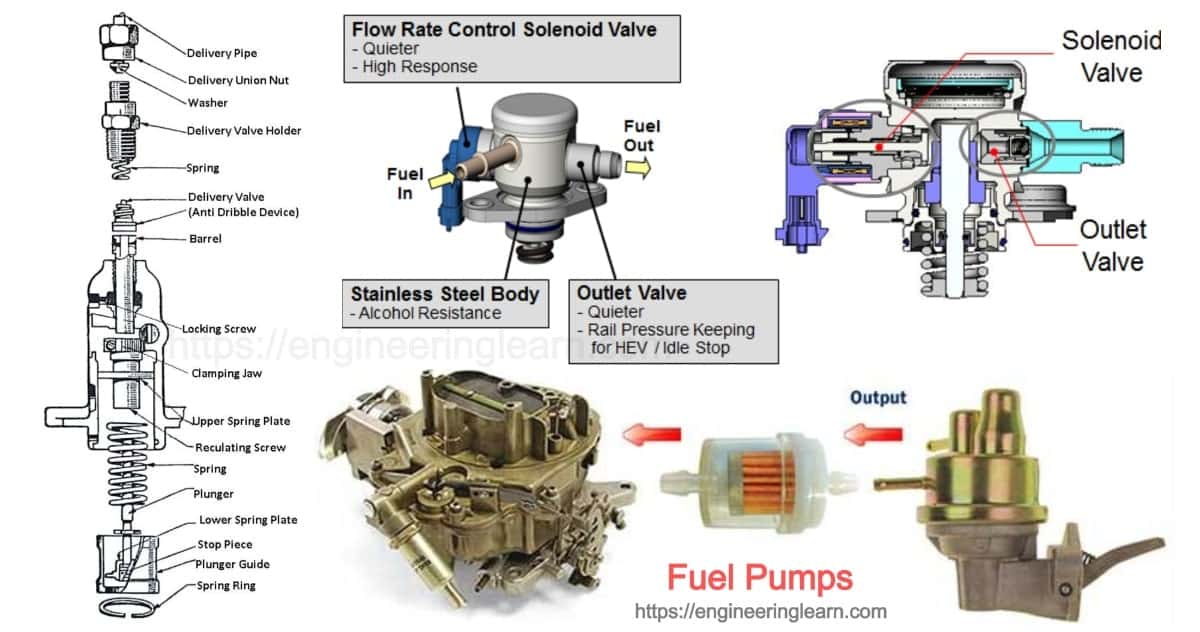

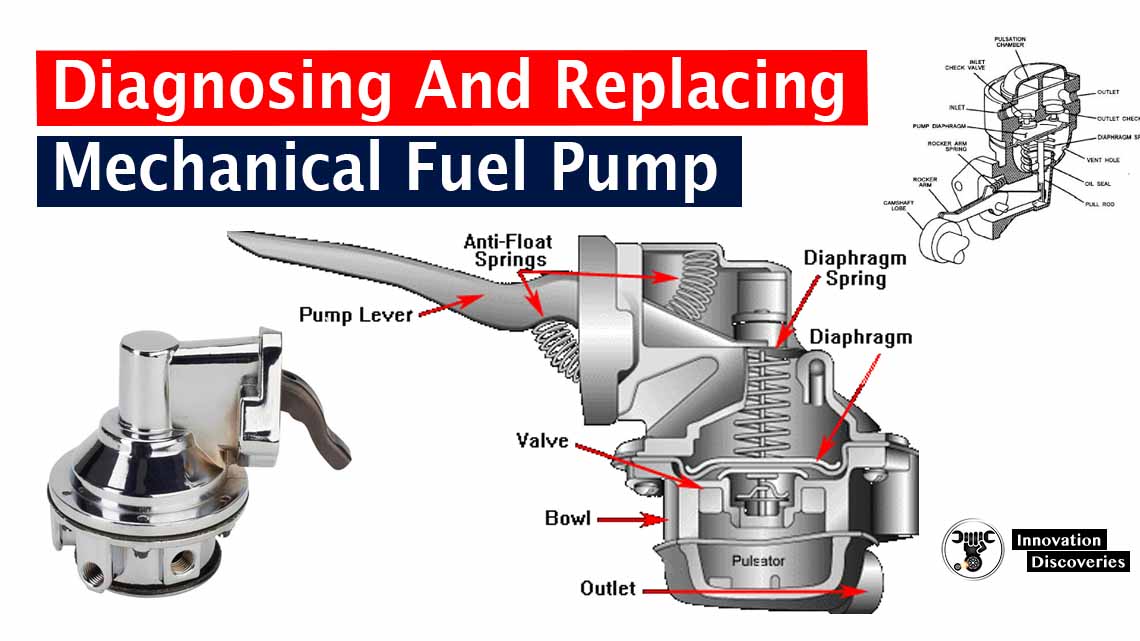

See whats inside this Mechanical Type Fuel Pump and how it works. By Speedway Tech Team. As RPM goes up fuel goes up.

It is the big nut on top of the front of the carb. I just did this to my holley 110 all you have to do is remove the screws on the bottom and rotate it then put the screws back in. Remove the two attaching bolts and extract the old fuel pump.

Disconnect the fuel pump from everything including the fuel inlet and outline lines. That is the fuel to the engine per revolution is essentially constant. Ask the assistant to turn the ignition key to ON direction without starting the engine.

With the gasket on the fuel pump insert the fuel pump arm into the hole in the spacer plate. Remove the central screw or nut from the top of the fuel pump housing. Detach the two bolts that connect the fuel pump to the engine.

The needle and seat come out with a 58 wrench and a srewdriver. Yes theyll spring open if you let themI clocked my Carter fuel pump on my 406 SBCRemoved all the screws with it clamped in a vice upside down so anything wanting out of there was held in place by one of my handsNo need to take it apart just turn the bottom to where you need it and youre good to go. Ground of fuel pump can be run to battery or chassis if chassis is grounded.

12 volt positive from key or fuel pump onoff switch will land on terminal 86. See whats inside this Mechanical Type Fuel Pump and how it works. If you hear any whirring sound for about 2 seconds that means the pump still receives power and is perfectly responsive.

In this episode of Motorhead Sweethearts we rebuild the mechanical fuel pump and try to get the Packard runningWe were not able to find the exact rebuild ki. Street Tech Speedway Mechanical Fuel Pumps Speedway Fuel Pressure Gauges Street. You may need to use and.

A C Mechanical Fuel Pump S U Electrical Fuel Pump Parts Working Pdf

Fuel Pump Construction Car Construction

Diagnosing And Replacing A Mechanical Fuel Pump

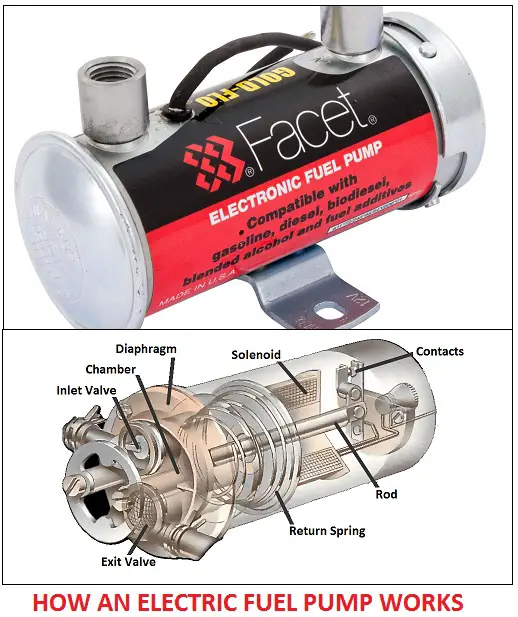

What Is A Fuel Pump How Does A Fuel Transfer Pump Work

0 comments

Post a Comment